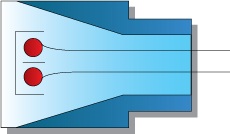

Back to the Basics: Sample Line Length and Diameter

A major delay in the response time of the analyzer comes from the length and inner diameter of the sample tubing.

The sample transport delay is increased by the square of the sample tube’s inside radius, and in direct proportion to its length. Doubling the inside diameter of the sample tube will quadruple the time delay it causes. Although the maintenance interval can be increased by the use of a large inner-diameter tube, such delays are usually unacceptable.